In industrial settings such as oil refineries, chemical plants, power stations, and mining sites, lighting plays a crucial role in maintaining visibility, productivity, and safety. However, traditional lighting systems can pose serious risks in such environments where flammable gases, vapors, or dust are present. This is where LED Explosion Proof Lighting becomes essential. Designed to prevent ignition in hazardous conditions, these specialized lighting fixtures ensure safety while delivering exceptional performance and energy efficiency.

What Is LED Explosion Proof Lighting?

LED Explosion Proof Lighting refers to light fixtures engineered to operate safely in environments containing potentially explosive materials. Unlike standard lights, which can spark or overheat, explosion-proof LED lights are built to contain any ignition that might occur within the fixture itself, preventing it from escaping and igniting the surrounding atmosphere. These lights comply with rigorous international safety standards and are commonly installed in hazardous areas classified as Zone 1, Zone 2, Class I Division 1, and Class I Division 2, depending on the presence of flammable substances.

How Do Explosion Proof Lights Work?

The concept behind explosion-proof lighting is simple yet highly effective. The fixture is enclosed within a robust housing, typically made from aluminum or stainless steel, designed to withstand internal explosions without rupturing. This containment design ensures that if a spark or heat source causes an ignition inside the fixture, it remains sealed and cannot ignite the surrounding gases or dust. Additionally, LED technology adds another layer of safety. Since LEDs emit minimal heat and do not rely on filaments, they significantly reduce the risk of sparks, making them ideal for hazardous zones.

Key Features of LED Explosion Proof Lights

LED explosion-proof lights are built for durability and long-lasting performance. Their corrosion-resistant materials such as aluminum or stainless steel make them ideal for harsh industrial conditions. They are highly energy-efficient, consuming less power compared to traditional lighting systems. Their lifespan can exceed 50,000 hours, providing bright and consistent illumination while requiring minimal maintenance. They are designed to operate under extreme temperatures and offer superior resistance to vibration and shock.

Applications of Explosion Proof LED Lighting

LED explosion-proof lights are used in many industries that deal with combustible materials or operate in hazardous conditions. They are essential in oil and gas refineries, chemical processing plants, petrochemical facilities, power generation plants, food and grain processing units, mining and marine operations, aircraft hangars, and large storage warehouses. These environments demand lighting solutions that guarantee both safety and operational efficiency.

Advantages of Using LED Explosion Proof Lighting

Safety is the top priority in any industrial setup. Explosion-proof lights minimize the risk of ignition and ensure the fixture remains sealed in case of an internal fault. They are energy and cost-efficient, providing substantial savings on electricity bills due to their low power consumption and high luminous output. Their long lifespan ensures reliability, reducing the need for frequent maintenance and replacements. These lights are also eco-friendly, free from harmful materials like mercury, and emit less CO₂. Improved visibility from bright, uniform lighting enhances worker concentration, reduces fatigue, and lowers accident risks.

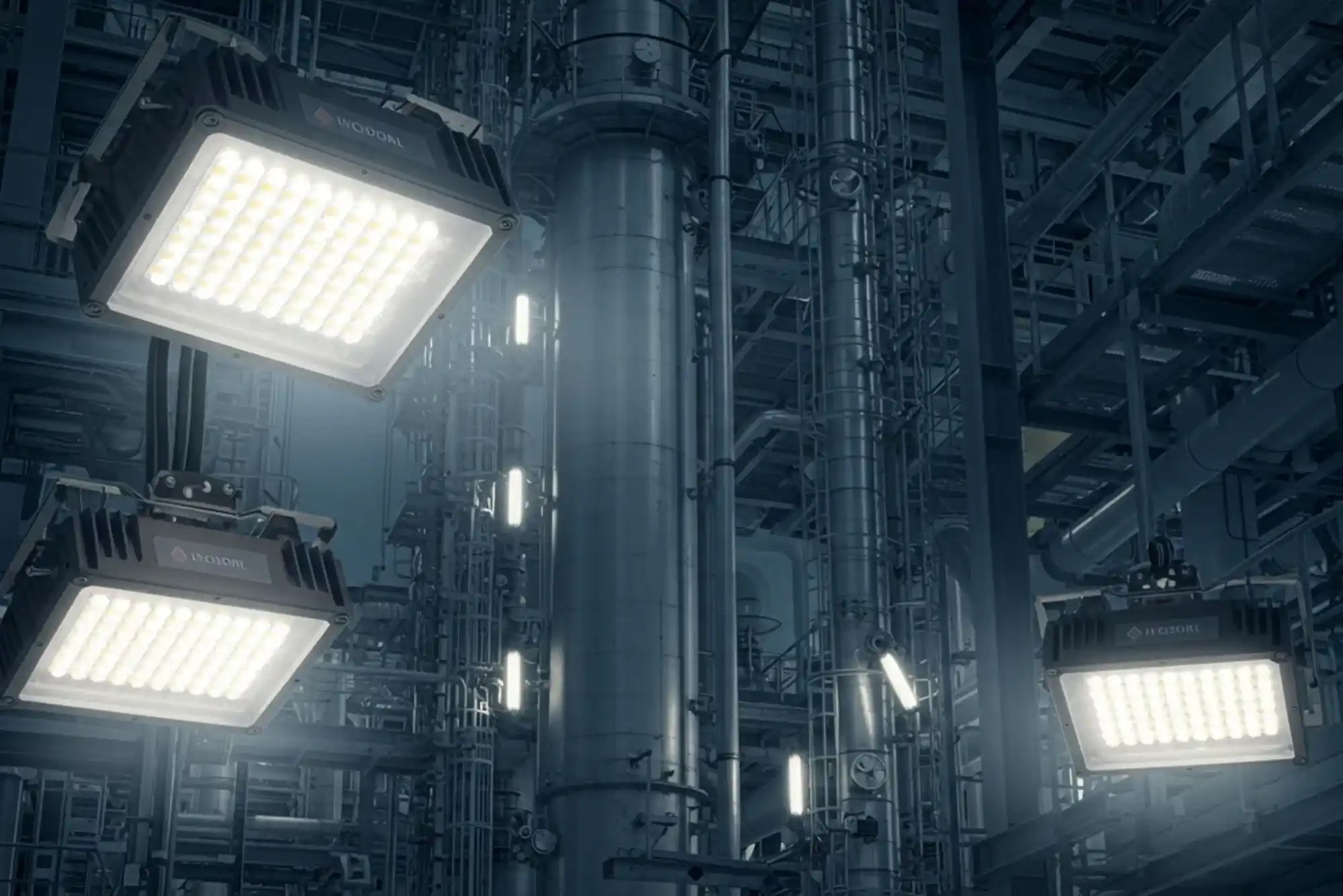

LED Explosion Proof Flood Lights: A Specialized Solution

LED Explosion Proof Flood Lights are a specialized form of explosion-proof lighting designed for illuminating large industrial spaces or outdoor hazardous zones. They combine high-intensity output with wide beam angles, making them suitable for outdoor refineries, loading docks, fuel storage areas, warehouses, and construction sites. Their rugged construction ensures resistance to shock, vibration, and corrosion, while their weatherproof design allows them to perform reliably in harsh conditions. With adjustable mounting options, they can be easily installed on walls, poles, or ceilings. Once installed, these lights require very little maintenance, ensuring long-term reliability and performance.

Choosing the Right LED Explosion Proof Lighting for Your Facility

Selecting the appropriate explosion-proof lighting system depends on factors such as hazard zone classification, mounting requirements, lumen output, and temperature rating. It is crucial to ensure that the selected lights are certified according to international safety standards such as ATEX, IECEx, or UL844. Working with a reliable manufacturer that specializes in explosion-proof lighting helps ensure that your facility remains compliant, energy-efficient, and well-protected.

Why Choose LED Explosion Proof Lights Over Conventional Lighting?

Traditional lighting technologies like halogen and fluorescent lights are less efficient, have shorter lifespans, and generate more heat, making them risky for hazardous environments. LED explosion-proof lights overcome these drawbacks by offering enhanced illumination, energy savings, and superior safety. Their low heat emission and solid-state construction make them ideal for long-term industrial use where reliability and protection are essential.

Conclusion

LED Explosion Proof Lighting provides the perfect combination of safety, efficiency, and durability for hazardous industrial environments. With advanced materials, energy-efficient LED technology, and superior engineering, these lights ensure reliable performance and compliance with safety standards. Whether you need compact fixtures for confined hazardous areas or powerful LED Explosion Proof Flood Lights for large-scale illumination, LED technology ensures consistent, safe, and efficient lighting even in the toughest conditions.